If you enjoy fast-paced action, try spending the day in the shoes of a contract manufacturer. A typical schedule may combine juggling conference calls with numerous clients who have diverse needs, testing materials in an in-house laboratory (or coordinating with a third-party lab), fine-tuning quality assurance procedures, evaluating new production equipment for your busy floor and ensuring the strict guidelines of good manufacturing practices are met at all times.

Contract manufacturers are the working gears of our industry, producing the finished goods for many of our industry's supplements, foods and personal care businesses. They frequently see industry trends ahead of the rest of us, as their clients race to test new ideas. Such speed cannot come at the cost of quality, which is increasingly in the spotlight with the publishing of the U.S. Food and Drug Administration's good manufacturing practices (GMPs) for dietary supplements in 2007.

Many industry contractors met these standards long before they became mandatory. Nonetheless, their implementation has caused some changes for contract manufacturers, particularly in this uncertain economic climate. The grouping of these two elements has put new pressures on contract manufacturers. In fact, says Siva P. Hari, Ph.D., president and CEO of Jarrow Industries, Inc., Santa Fe Springs, CA, it is "forcing the fast-rearrangement of price, product, quality and label claim issues for both marketers and contract manufacturers and packagers."

Many industry contractors met these standards long before they became mandatory. Nonetheless, their implementation has caused some changes for contract manufacturers, particularly in this uncertain economic climate. The grouping of these two elements has put new pressures on contract manufacturers. In fact, says Siva P. Hari, Ph.D., president and CEO of Jarrow Industries, Inc., Santa Fe Springs, CA, it is "forcing the fast-rearrangement of price, product, quality and label claim issues for both marketers and contract manufacturers and packagers."

He explains that marketers and entrepreneurs "want to make a big splash and catch big cash" by "identifying a trendy product or ingredient or formula, jazzing up marketing and promotion and forcing the contract manufacturer to make it for the least amount of money/cost."

This can be a tall order now that operational costs are up and the spotlight is shining brighter than ever before on quality. John P. Kelly, vice president of contract manufacturing and private label at Nature's Products Inc., Sunrise, FL, notes that contractors must now offer the "right combination of quality, service and value—in a timely fashion." And, businesses must be flexible enough to respond to new product trends as they develop.

Hari agrees and notes that contract manufacturers must develop a new business model to comply with FDA's stringent manufacturing requirements and contain costs at the same time. "These are antithetical requirements since quality and low-cost are on opposite ends of the monetary scale and aptly fit the adage: beer budget and champagne taste," says Hari. But, industry contract manufacturers are finding new ways to meet this need.

How the Right Partnership Offers Top Value

One way of achieving this marriage of quality, service and value is finding the right partnership. Nicole Lemus, director of sales, contract manufacturing at Century Foods International, Sparta, WI, notes that "in tough economic times, it is important to partner with a professional contract manufacturer who can help you maximize efficiencies." A key part of getting the highest-quality product at the lowest-possible cost is that "everyone should be doing only what they do well." For example, companies whose strengths are product marketing and promotion should consider finding a good contract manufacturer to make the most of their production dollar.

This strategy will offer benefits without the overhead costs or headache of a manufacturing operation, says Steve Holtby, president and CEO of Soft Gel Technologies, Inc., Los Angeles, CA. "By outsourcing manufacturing to a company that has the knowledge and expertise to produce a quality finished product, a customer can focus on other aspects of business, including branding, marketing, and selling their finished goods."

This strategy will offer benefits without the overhead costs or headache of a manufacturing operation, says Steve Holtby, president and CEO of Soft Gel Technologies, Inc., Los Angeles, CA. "By outsourcing manufacturing to a company that has the knowledge and expertise to produce a quality finished product, a customer can focus on other aspects of business, including branding, marketing, and selling their finished goods."

Jeffrey Reingold, director of R&D at Contract Pharmacal Corp. (CPC), Hauppauge, NY, offers an example from the pharmaceutical industry about how contract manufacturing can save you money: "In an effort to limit capital investments and reduce overhead as well as gain access to the wealth of expertise and technological advances offered by contract manufacturing firms, our customers have been outsourcing more substantial parts of their business. Many Big Pharma companies such as Pfizer and GlaxoSmithKline have sold off manufacturing facilities in the past year creating additional opportunities."

Contract manufacturers that can best economize their clients' production projects are those that understand their clients the best. For example, says Eugene Ung of Best Formulations, City of Industry, CA, "It's extremely important for the contract manufacturer to understand the distribution model, customer base, current products, etc. in order to formulate and manufacture a product that will work successfully with that particular client."

Ung adds, "We work with customers of all sizes in all distribution channels...A particular product for one customer could be their best seller. That same product for another customer may completely bomb. So it's important that the contract manufacturer has experience in working with a wide range of customers in different distribution channels to really understand what may or may not work for the customer."

Of note, contractors who understand the complex ins and outs of product development can help economize time and money. For example, knowledgeable contract manufacturers and their partners can work closely together on fine-tuning a product formulation before investing in something that isn't stable or cost-effective. Says Kirk Neal, president of Arizona Nutritional Supplements (ANS), Chandler, AZ, "It is in the best interest of both parties to make sure the formula meets the customer's needs, while being able to be mass produced at a reasonable cost. The manufacturer is uniquely able to manage the supply chain to make sure if volumes increase, they are able to meet their customer's needs."

Of note, contractors who understand the complex ins and outs of product development can help economize time and money. For example, knowledgeable contract manufacturers and their partners can work closely together on fine-tuning a product formulation before investing in something that isn't stable or cost-effective. Says Kirk Neal, president of Arizona Nutritional Supplements (ANS), Chandler, AZ, "It is in the best interest of both parties to make sure the formula meets the customer's needs, while being able to be mass produced at a reasonable cost. The manufacturer is uniquely able to manage the supply chain to make sure if volumes increase, they are able to meet their customer's needs."

In agreement is Jim Cudahy, president and chief operating officer of Sabinsa Corporation, Piscataway, NJ, who notes, "both parties leverage and assist each other on their corresponding strengths and weaknesses. With our manufacturing expertise (both in our ingredients and finished goods), we offer advice and council in new developments, functionality, manufacturability and cost effectiveness. This sharing of information and expertise is a part of the value added by a good contract manufacturer."

Lynn Ware, general manager of Fusion Formulations (formerly American Supplement Technologies), Tempe, AZ, offers some additional insight into how a contract manufacturer can assist product development: "When our technical staff sees a formula with room for improvement, they discuss the details with the client helping them understand what, why and how the change will benefit the formula. The integrity of the finished product is first and foremost. We recognize that when our clients are successful, we are successful."

And, if done well, with the right timing and with customization for each client, this tool can help save the product manufacturer time and resources. Says Kenn Israel, vice president of marketing at Robinson Pharma, Santa Ana, CA, "Typically, [product improvement] is a relatively easy process during the product development/formulation stage and significantly more challenging once the product has entered production or is in the market. This creates a big incentive to get the product right the first time. The nature of the relationship may also create a slightly greater disincentive towards highly innovative formula development and ingredient sourcing. Partnering between the manufacturer and marketer and keeping communication open—even after the product has shipped—is key to maintaining a successful relationship. If something is not working for either party it is important to communicate this as early as possible."

And, if done well, with the right timing and with customization for each client, this tool can help save the product manufacturer time and resources. Says Kenn Israel, vice president of marketing at Robinson Pharma, Santa Ana, CA, "Typically, [product improvement] is a relatively easy process during the product development/formulation stage and significantly more challenging once the product has entered production or is in the market. This creates a big incentive to get the product right the first time. The nature of the relationship may also create a slightly greater disincentive towards highly innovative formula development and ingredient sourcing. Partnering between the manufacturer and marketer and keeping communication open—even after the product has shipped—is key to maintaining a successful relationship. If something is not working for either party it is important to communicate this as early as possible."

Also noting the importance of R&D in the contractor–client relationship is Hari, who explains how spending on R&D is changing in this economic climate: "Suddenly, R&D and R&D budget (a novel word for small and medium-size marketers and private label customers) now enter the lexicon of discussion between the client and contract manufacturer. Similarly, legal and binding agreements that spell out the obligations agreed on or waived for complying to the regulatory requirements between the client and contract manufacturer."

At the same time, product marketers need to understand that they cannot pay bottom-dollar for top quality. Instead, says Hari, we are moving to "sensible and cost-effective product design, dosage and benefit ratio." Further, there will be shared liabilities and responsibilities between both parties "to maintain the label claim, integrity, quality, stability and adverse-event/recall protocols" before and after the product is sold. "However," says Hari, "the big question that keeps the clients and manufacturers alike sleepless will be who will pay for it and how do you wrap into high-price to the consumer in these dire national/global economic recessionary times."

A Silvery Green Lining to Economic Trouble

Despite the rocky economy times, contract manufacturers report that the rising consumer interest in natural products has kept many contractors stable. Says Kelly, "The demographics for our category are sound and consumers are increasing turning towards self-care. The result is an increase in demand for our products, and reliable contract services."

Keith Frankel, president and CEO of Vitaquest and Garden State Nutritionals (GSN), West Caldwell, NJ, notes, "Historically, the nutritional business has been somewhat insulated from economic swings, particularly if the producer is spread across a variety of markets. Diversification internationally as well as throughout various industries helps to reduce the economic risks. Clearly, costs have been soaring for the past two years which has affected margins, but it appears as though some of these costs are coming back to normal ranges."

That being said, all are affected in some way by the slow economy and rising material/energy costs. "Our sales have remained strong," says Neal, "but it has been difficult to keep margins at an acceptable level with the increased costs. The increased costs have forced prices to be raised even during the economic downturn." As a result, he notes some customers' value lines are showing more growth, though some higher-end products have slowed. "This is a trend we expect to continue as the economy continues to struggle," he predicts.

That being said, all are affected in some way by the slow economy and rising material/energy costs. "Our sales have remained strong," says Neal, "but it has been difficult to keep margins at an acceptable level with the increased costs. The increased costs have forced prices to be raised even during the economic downturn." As a result, he notes some customers' value lines are showing more growth, though some higher-end products have slowed. "This is a trend we expect to continue as the economy continues to struggle," he predicts.

Because of rising material and transportation expenses, Ware notes that her company "continually looks for ways to trim costs so that we can continue to provide value to our clients."

But, an encouraging silver lining to the rising materials costs may be innovations in lean and green manufacturing. "Contract manufacturers are now facing environmental issues," says Holtby. "Depletion of natural resources has become a common concern, which is why lean manufacturing processes have replaced methods of the past."

Holtby explains that such "supply chain environmental management" is beneficial to all involved. "Lean manufacturing is about zero waste. Lean efforts to eliminate defects and errors, overproduction and inventory can also reduce energy and water use, and solid and hazardous waste," he says. Holtby also predicts that as energy and material costs rise in the future, manufacturers will need to adopt sustainability strategies to save money.

An Investment in Future Growth

When brainstorming about the most economical and productive ways to expand a product line, consider consulting a contract manufacturer. "We have worked very closely with our vendors to be a point of reference on the dissemination of the latest technologies," says Frankel. "We believe we can help our clients to best translate the data and marketing position of new ingredients and technologies and position in the right delivery system for the appropriate condition to the right market. Many of our new clients come to GSN specifically for our assistance in making their products work better, run better and present to market better. We'll work on every level to make that happen from formulations, flavors, product appearance, package design and engineering to point-of-sale materials. We'll do whatever we can to help our clients maximize their products' success."

A good contract manufacturer will not only be aware of new trends in the nutritional product market, but also will proactively respond to them. Says Holtby, "[New technologies] require staff education and training and possible investment in new equipment. With the advent of the new FDA GMPs for dietary supplements, contract manufacturers must advise customers of the implications of the new regulations."

So, what areas are the fastest growing, according to contract manufacturers contacted for this article?

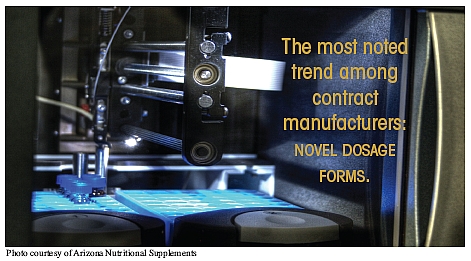

The most noted trend among industry insiders was interest in dosage forms other than regular tablets, hard shell capsules and powders. For example, Ung notes that soft gel manufacturing is increasingly requested. The reason? According to Ung, they are "hermetically sealed, easier to swallow, have a higher perceived quality." They have increased in popularity thanks to oil-based nutrients like omega-3 essential fatty acids.

The most noted trend among industry insiders was interest in dosage forms other than regular tablets, hard shell capsules and powders. For example, Ung notes that soft gel manufacturing is increasingly requested. The reason? According to Ung, they are "hermetically sealed, easier to swallow, have a higher perceived quality." They have increased in popularity thanks to oil-based nutrients like omega-3 essential fatty acids.

Since manufacturing this dosage form is not easy, "working with a softgel contract manufacturer will allow the company to introduce new soft gel products to their offerings without having the great expense of setting up a softgel operation in house," Ung says.

In terms of the dosage form trend, Reingold notes that customers are looking for modified time-release and combination products. "Customers are excited about the one-stop product that has multiple indications—whether it is long lasting or multi-functional," he says, noting that his company has reacted to this trend by installing new high-shear granulation and fluid-bed drying equipment.

Another area of growth is in products linked to convenience such as stick packs. "Stick packs have been the staple of Japanese market due to their obsessive vending machine culture for everything," says Hari. The advantage of stick packs, he says, is that they provide "the ultimate in convenience, and single-dose-serving of vitamins, minerals or nutritional supplements that are ready, easy to mix in the drink of choice and to enjoy the flavor and taste of the drink with added benefits of health-supplements."

Similarly, Frankel notes that Vitaquest has been focusing on the inclusion of custom beverages, one-shots, stick packs and other nutritional delivery systems that "add to the arsenal of opportunity to touch the consumer throughout the day as well as deliver novel ingredients in a more consumer-friendly and added value manner."

Also experiencing increased demand are condition-specific products intended for joint care, cardiovascular benefits, eye health, memory aides, blood sugar control and more. These multinutrient formulas are well-suited for contract manufacturing. "Formulating products with various ingredients requires specific knowledge and experience to create a product that is able to be manufactured and will be shelf stable. It's easy to say ‘I want a softgel with these 60 ingredients in it, but it's much more difficult to make that a reality," says Ung.

Interest in organic food and supplement ingredients is another notable trend. As a result, many contractors are getting organic certified and are offering clients new organic offerings like tablets and powders, says Neal. "It is a complicated and time-consuming process, but with the increased interest, it is an exciting arena to be in," he notes.

Holtby agrees that organic certification of organic ingredients has its difficulties. "This poses a challenge of qualifying a supplier that meets all of the specifications for a particular ingredient," he says, adding, "Managing the various suppliers and making sure the proper materials are being procured and analyzed could potentially add to the lead time for producing a product."

Another trend may be the entrance of personal care companies into the supplements market and vice versa. "This has created extra demand for contract manufacturing services as contract manufacturers allow companies to introduce new products at a relatively low cost in terms of product development, machine costs, operational expenses, etc.," says Ung.

Frankel notes the integration of topical and edible products for anti-aging effects, which "have really helped move the industry forward…the coupling of efficacious nutritional and topical therapies makes for a more productive product as well as better customer satisfaction and continuity."

Other notable hot products include:

- Probiotics,

- Effervescent tablets,

- Liquids,

- Omega-3s,

- Weight-loss products,

- Vitamin D and

- Functional beverages.

Narrowing Down the Search

Narrowing Down the Search

With so many contract manufacturers out there, it can be overwhelming to identify a new partner. "A good relationship is key; not just between one company's sales staff and the other company's purchasing staff, but vertically between both organizations," says Ware of Fusion Formulations. "Understanding each other's business leads to success for both."

- The first step to finding a good manufacturing partner, according to Sabinsa's Cudahy, is to understand your needs. He advises that you ask yourself, "Do I need someone to develop a product, help with converting a concept into a commercial product or make the product that I already know works?"

- Explore the market, says Cudahy, looking for manufacturers that are compliant and the right size for your needs. "Get a written cost estimate with the answers to all your questions and assumptions, before you agree to working together," he suggests. And Israel adds, "Find a vendor where the minimum and maximum run sizes work with your requirements, meeting initial batch sizes can be as challenging as runaway success."

- Make sure you identify a manufacturer with consistent lead times, says Holtby, "so that it does not create out-of-stock or other inventory issues for the customer. Its capacity should be sufficient to handle current volumes and possible future increases, and to expand operations if needed down the line."

- Don't underestimate the manufacturer's experience and resources, says Frankel, as these elements can help the product marketer grow and help avoid pitfalls. "Experience and flexibility are the keys to success," he says. "This is a very dynamic market and a company who has production flexibility, packaging flexibility, proper GMPs, international expertise, retail experience, direct response know-how and is adept at understanding the clients objectives will be a better partner than your typical nuts and bolts producer."

- To that end, may sure your dosage form and packaging requirements match the manufacturer's expertise. "If the vendor only has a hammer, then every problem becomes a nail," says Israel, who adds, "Selecting the correct delivery system can maximize or spoil success. Is the choice in delivery system driven by what the vendor offers? Does the vendor currently work with the delivery system you require?"

-

Ask questions about their analytical laboratories. "The biggest challenge for contract manufacturers of dietary supplements is the requirement for full testing of all active dietary ingredients," says Reingold. "CPC reacted to this new regulation by more than doubling the size of our analytical laboratory and implementing full testing on products—testing to confirm the FDA's requisite of identity, purity, quality, strength and composition of dietary supplements."

Ask questions about their analytical laboratories. "The biggest challenge for contract manufacturers of dietary supplements is the requirement for full testing of all active dietary ingredients," says Reingold. "CPC reacted to this new regulation by more than doubling the size of our analytical laboratory and implementing full testing on products—testing to confirm the FDA's requisite of identity, purity, quality, strength and composition of dietary supplements." - Lemus of Century Foods suggests finding a contractor with strong customer service. "Using a contract manufacturer should make the customer's job easier, knowing that all aspects of a project, from development, quality, processing and packaging are taken care of," she says. "If a contract manufacturer is able to offer a full team to serve the customer's needs, and maintains the highest quality standards, it's a win–win solution."

- Decide how much per unit you want to pay. "Knowing your price model at the beginning of a project is critical to the success of your market plan and financial success," says Israel. "Communicate this information early in the process as it will save a lot of time or result in modifications that will yield product success." Be clear on all payment and terms.

Ung offers up these specific questions to ask: - Are you compliant with the FDA GMPs? Are you GMP certified?

- Do other customers audit you? "Some manufacturers discourage customer audits, and you have to ask yourself why," says Ung. "The contract manufacturer must be seen as an extension of your business, and would you allow one of your departments to say ‘no' to an internal audit?"

- Do you do pilot runs? Such small-scale runs help to test the finished product's stability and iron out any kinks.

- What are your minimums? This can help determine whether the manufacturer is price competitive. "If you're a very small company, it's best to find a company that specializes in smaller runs as their prices will be more competitive," says Ung.

- What are your R&D and formulation services? Do you have experience in manufacturing certain types of products?

Once you've thinned out the pack, visit your top choices. "At a minimum, a full tour of all the operations, laboratory and a short audit of their quality procedures will tell volumes about what kind of company they are," says Neal. "While there, ask to see any certifications as well. Although a third-party certification such as NSF or USP is not an end all, it is a good start." And use the face-to-face time to get to know the staff; make sure you're comfortable with them and you share similar values. "It is much easier to work with companies that have closely aligned attitudes about how business should be conducted. Good partnerships take a bit of time to develop, but pay major dividends down the road," says Neal.

Overall, Kelly of Natural Products, Inc. advises, "Select one that cannot only meet your needs for today, but also tomorrow. You want an organization that is seeking a long-term partnership, not just some new business." WF

|

New Offerings from Contract Manufacturers |

Published in WholeFoods Magazine, January 2009