1. Time savings.“Working with a contract manufacturer streamlines the entire manufacturing experience from birth of conception to the moment the finished product leaves the facility destined for the consumer’s hands,” says Scott Steinford, CEO, Health Wright Products (HWP). “A good contract manufacturer will assist from the start by sharing their market and formulation expertise to assist with product development. Contract manufacturers also understand how to produce products that will adhere to GMPs and meet label claims through shelf life. Contract manufacturers also have the right technology and equipment to produce high quality products. At HWP, we invest in pharmaceutical grade and cutting edge equipment and have optimized our environment through temperature and humidity controls.”

2. Innovation.“Whether it’s a startup customer or mature brand, a good contract manufacturer can help develop innovative new products that go to market faster and follow industry trends—with better economics,” says Michael Young, Executive VP, Sales & Marketing, Vitaquest International. “If a company-customer is new to the business, a good contract manufacturer can provide resources that a company doesn’t have—from formulation development, to manufacturing and packaging—into a fully realized commercial offering. Even for very large companies, a good contract manufacturer with global scale manufacturing capabilities and world leading quality systems in place can help a company expand capacity, reduce costs and move to market faster.”

3. Specialized expertise.“There is a need for highly educated and trained personnel with multiple levels of specialization,” says Kaufman. “Over the years, we have gained extensive valuable manufacturing experience given the various products that we manufacture. OLDs can benefit from the experiences of the CM and further reduce the cost to OLDs of producing a finished product by avoiding costly development costs of new formulations.”

Steve Holtby, President & CEO, Soft Gel Technologies, Inc., seconds that, noting that contract manufacturers can provide instant expertise and infrastructure. This, he says, “can allow companies to expand their product offerings quickly without massive capital outlay.” That can be especially important with challenging products. “Many companies are too small to warrant starting their own manufacturing facility, or they do not want to deal with all the regulations needed to comply. This is especially true for softgels, which is a unique and complicated process. One of the challenges of making softgels is that the operators who run the encapsulation machine have to be well-trained and competent to learn the techniques for a smooth and efficient operation. In addition when formulating products, specific shell/fill interactions, which include chemical reactions of fill components with the gelatin and the plasticizer, and migration of fill components in or through the shell and vice versa, have to be considered.”

4. Regulatory knowledge.“The manufacturing process has become more sophisticated in terms of testing for quality and new specifications to manufacture products to,” says Kaufman. “As federal and state regulations continue to increase, the manufacturing process for dietary supplements will not be getting any easier. As a result, CMs have to invest in new technology and have had to educate themselves and their customers to stay abreast on new developments within the dietary supplement industry.”

5. Relief from daily headaches.“Global economic forces also affect today’s business climate; many companies have to compete for an increasingly competitive market share,” says Holtby. “Contract companies that are able to take a lot of the technical load are attractive, because it allows brand owners to completely focus on making sales, advertising, and marketing the product. By outsourcing production, there is no need to purchase or rent production facilities, buy equipment, qualify and purchase raw materials, or hire and train employees to produce the goods. There are also no headaches from dealing with employees who fail to report to work, equipment that breaks down, or any of the other minor details that any manufacturing company must face daily.”

6. Freedom to focus.“By selecting an experienced contract manufacturing partner you can leverage the expertise of their team (i.e. sales representatives, project managers, etc.),” says NutraScience Vice President of Contract Manufacturing, Vincent Tricarico. “This gives the brand owner the opportunity to focus their attention on the other aspects of their business, such as sales and marketing.”

Tricarico’s advice: “I’d recommend that new brand owners identify a contract manufacturer that offers turnkey services under one roof—manufacturing, packaging, labeling, and fulfillment. This will save the brand owner a countless amount of stress because all aspects of their project are being completed by one company versus multiple vendors; it’ll also cut down on the amount of time they’re waiting for their project to be completed. Last, but not least, I’d advise new brand owners to partner with an experienced CM that has a proven track record of success. At the end of the day, you have to remember that the finished product you bring to the market will be purchased and consumed by another individual. Trying to cut corners to save a few dollars will ultimately lead to the demise of your brand.”

Another company offering turn-key solutions is ADH Health Products, which provides a variety of dietary supplements, including vitamins, minerals, botanicals, probiotics, enzymes, and specialty nutraceuticals. The company says on its site that modifying a traditional dosage is its specialty: “If you’re looking to match a desired flavor profile, alter a release pattern, or develop a proprietary process, we’re your partner.”

Considerations in the the Age of COVID-19

“COVID has impacted many industries and many parts of the supply chain,” says Kaufman. “The supplement industry is not an exception in this case. Raw materials that are typically regularly in-stock have been pre-ordered months in advance to secure their supply due to increased supplement demand. Also, packaging components that were most readily available are suddenly experiencing longer than usual lead times. The disruptions in the supply chain could possibly impact a brands’ ability to get their product produced in a timely manner and maintain a consistent level of stock. At the start of the pandemic for example, several large chain pharmacy and grocery stores were out of stock of common zinc, Vitamin D, and Vitamin C products. Manufactures are still playing catch-up to the surge in demand for supplements in 2020, so longer lead times have been consistent across the board.”Tricarico notes the challenges as well. “COVID-19 has certainly created unprecedented times and challenges for every CM in the industry—including NutraScience Labs. For the most part, our supply chain has held together well—we’ve had our hiccups here and there (like every other CM), but we’ve managed through it. One area of concern we had was attendance in the facility where employees were fearful about coming to work. Thankfully with the right protocols in place a good CM will overcome that fear. We are seeing a massive increase in demand for probiotics, which has created some backlog in receiving those specific raw materials. Since the demand on packaging has increased for items such as hand sanitizers, we have also seen specific delays on certain size bottles and lids. Again, a good contract manufacturer will have inventory on hand that can overcome this issue.”

In addition to supply chain disruptions, in January a contract manufacturer doing business as ABH Nature’s Products, Inc., ABH Pharma, Inc., and Stocknutra.com, Inc. announced a nationwide recall of all lots of its dietary supplement products pursuant to a Consent Decree entered by the U.S. District Court for the Eastern District of New York. The recall included all lots of all dietary supplement products manufactured and sold between January 2013 and November 2019 (1).

InWholeFoodsMagazine’s 2020 Forecast, Len Monheit, CEO, Trust Transparency Center (TTC), identified low-quality products from contract manufacturers as a top concern for industry this year. “We’ve had an acknowledged black opaque box in the middle of our supply chains forever,” Monheit said. “It’s Contract Manufacturing and to a certain extent all contract services including analytical labs. While some of these service providers are world class with a focus on quality and sourcing, many are low barrier to entry operations that reverse engineer leading products at a fraction of the cost, taking every shortcut imaginable. Brands don’t know what they don’t know, especially Internet (entry) brands, don’t know the questions they should ask of these service providers and since they’re startups, the minimums are quite attractive. This is an industry Achilles heel.”

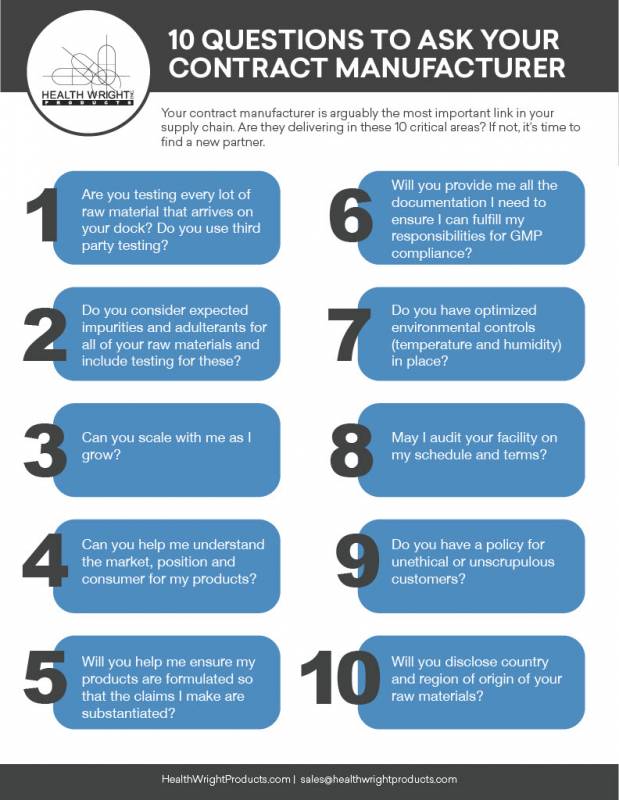

Ask This Before Partnering

Our experts outline key points a potential customer should ask a prospective contract manufacturer:- How long have you been in business, but even more importantly how much experience does the team working on your project have?

- What certifications do you have? Tricarico says an absolute must is cGMP certified by a 3rd party. In addition to asking if the company is FDA cGMP compliant, Holtby advises asking, “Who has certified you?” Also speaking to certifications, Young says, “Another important question has to do with quality systems, from sourcing and ingredient traceability, though formulations and finished product. This cannot be emphasized enough. We would ask if they had FSSC 22000 Food Safety Certification. It is the most advanced food safety system in the nutraceutical industry today. Vitaquest received this gold standard certification in 2018.”

- Do you have any 483s? “A Form 483 is used by the FDA to designate a non-compliance issue after the manufacturer’s facility/facilities have been inspected,” says Tricarico. “While receiving a 483 isn’t the end of the world, receiving multiple citations or failing to address an issue should be a major red flag.”

- What does your manufacturing process look like? A qualified CM should be able to walk you through the process from start to finish without issue, says Tricarico. Holtby suggests having them lay it all out, asking: Explain to me in detail the new product process, including lead time, possible delays, and what to expect. Everyone can make a good product when everything goes as planned, says Holtby, who suggests asking, “What are your procedures to handle unexpected problems such as testing issues, raw material shortages, etc.?”

- How do you qualify your raw materials? Do you provide the source, testing, and full documentation? “Contract manufacturers face the challenge of growing the business and keeping up with regulatory issues,” Holtby says. “With the advent of the FDA GMPs for dietary supplements, contract manufacturers must have formal training programs in place to ensure that personnel have a thorough knowledge of GMPs and Standard Operating Procedures (SOPs) and follow them. Record keeping and documentation are crucial components to ensure GMP compliance and continued certification. Complete and detailed batch records need to be maintained for traceability purposes.”

- How do you store raw materials and finished products? “This is especially important for probiotics, which can be unstable,” says Steinford. “HWP has invested in cooler storage to ensure raw materials and finished products are stored in an optimal environment.”

- What is the turnover rate within your company?

- What is your most common planned and unplanned deviation during manufacturing?

- Will my project be done fully within your company? Young points out that not all contract manufacturers have the in-house capability to handle all phases and types of projects. “At Vitaquest, we make more than 4,000 custom formulas for more than 500 brands in 40 countries. Our teams help launch more than 2,000 new products a year. All in-house.”

- What are the minimum order quantities (MOQ)? “As a brand, you want to make certain that your order quantity and turns per year is in the right ballpark of the contract manufacturer’s regular order volumes,” advises Kaufman. “CMs can make exceptions to an order volume, yet to ensure that they can give you the right amount of service that you need, it is important to make certain that you and the CM are the right fit, form, and function for each other.”

- What is your quality control process? Are all raw materials tested and released by the quality control department? “Paragon has an in-house laboratory, which means it will typically be able to verify and release products with a quicker turnaround time than a facility that uses only third-party labs,” says Kaufman. “Also, a quality assurance function should be present to oversee overall manufacturing and quality functions.”

- How do you determine if your design for manufacturability is feasible? “Each product and raw material that goes into a product has its own nuances,” Kaufman explains. “If you work with a manufacturer that has experience with that ingredient or a similar product, then they will be better suited to manufacture your product than a manufacturer that does not have experience with it.”

- Can I come today and visit your facility? Holtby recommends asking this. Even if you can’t come in person due to COVID, the CM should welcome you. And that’s true virtually as well, whether visiting a potential partner or checking on your current partner. “While inspecting and auditing contract manufacturers may be more difficult as a result of COVID-19, the reality is it is no excuse to alter or delay the audit process of your contract manufacturer,” stresses Steinford. Things to consider: “Not all contract manufacturers are the same, so it is important to determine the strengths and weaknesses of each. Simply because a contract manufacturer says they can do everything, it is not automatic that they do everything well. To that point, it is equally important to verify the company’s expertise within each format of delivery offered. Clients should audit their contract manufacturer. With COVID, some may not be able to visit in person, but in person inspections should be welcome by the contract manufacturer. If you can’t go in person, ask for a virtual tour and audit the inspection reports. Check FDA’s list of inspections and infractions to see if the contract manufacturer has failed or passed.” To help guide the visit, HWP has this easy-reference question sheet:

A few additional things to consider during these discussions, according to Tricarico: “How often is the CM you’re speaking to saying ‘no?’ You should be wary of contract manufacturers who constantly say ‘yes.’ Any qualified CM should be able to tell a prospective client that some things simply can’t be done and there are certain products and tasks that other manufacturers might be able to do better.”

Be prepared to answer questions, too. “On the client side, at Health Wright Products, we want to determine we are the best option to meet our client’s needs for both parties involved,” says Steinford. “Clients should be prepared to share their product vision and goals. A CM will also need to know typical order quantities, target prices, launch dates, annual forecast, previous manufacturing history, budget, quality expectations, etc.”

2021 Trendspotting

As COVID-19 concerns continue, how are consumer priorities shifting? What categories will drive sales in 2021? What are different demographics focusing on? Our experts shared insights that can help you meet consumer demands, and boost your bottom line.The two main growth drivers in the dietary supplement industry: baby boomers and millennials, says Steinford. “Rising health care costs coupled with the impact of COVID-19 have encouraged consumers to look toward the dietary supplement industry to support preventive health.”

The surge in immunity-boosting supplement sales is likely here to stay for some time as people make supplement intake a healthy habit, adds Kaufman, who notes that we’ll be seeing more research exploring the benefits of supplements for immunity in the future. Tricarico seconds that: “I firmly believe that COVID-19 has made everyone realize that health is the number one asset in all of our lives and folks have jumped on the proactive approach by using dietary supplements to provide some extra insurance against illness. I think this trend will continue even after COVID-19 is in our rear view mirror.”

Beyond immunity, our experts pointed to several in-demand categories: Holtby lists healthy aging, anti-inflammatory, energy, sexual vitality, weight loss, sleep aids, and anti-anxiety. Vitaquest’s Young adds stress management and cognitive health. Steinford also places digestive health on the list, along with probiotics and the many benefits they offer. “As probiotics continue to be in high demand, market experts continue to expand the probiotic category. From weight management to skincare, innovative research continues to demonstrate the multifaceted function that each individual strain can provide.”

Taking a closer look at the younger demographic, Steinford adds, “With the rise of trendy new brands and subscription-based services, the millennial generation is diving head first into the supplement pool—especially in the areas of beauty from within, sleep management energy and focus.”

Beyond health benefits, Tricarico points to probiotics along with greens formulas, natural flavors and sweeteners, and natural sources of energy. “Simple is the key; consumers want easy-to-read labels, with simple formulations. The more transparent a brand owner can be with a consumer, the more trust they can build, which will lead to an initial purchase and hopefully future re-orders.”

Consumers look for bioavailability, potency and purity as key factors in their supplement purchases, says Holtby. “Another trend is that consumers want ‘natural’ supplements—those without fillers or chemicals, products made with natural and/or hypoallergenic ingredients and gentle/buffered formulations. Many avoid supplements with artificial colors/flavors. Whole food supplements are a growing segment in this supplement category.”

Before signing a deal

Offering a final caution for brands before signing on with a contract manufacturer, Holtby stresses: “Contract manufacturers have always competed against each other, but in an increasingly crowded, growing marketplace, the need for companies to differentiate their brands from the competition is important. Contractors based in North America find it increasingly difficult to compete with manufacturers based in countries, like China and India, where operations are a fraction of the cost. Quality vs. price point is often an issue. Many companies focus on price when choosing a contract manufacturer, but forget that quality, service, and on-time delivery are factors that are more important in making a decision. Good contract manufacturers will have excellent quality systems in place; they will have full transparency throughout the process; and provide experienced service and on-time delivery to meet product requirements.”WFReferences

- WholeFoods Magazine Staff, "Contract Manufacturer Issues Major Recall of Dietary Supplements," WholeFoods Magazine. Posted 01/23/2020. Accessed 09/01/2020. https://wholefoodsmagazine.com/supplements/news-supplements/contract-manufacturer-issues-major-recall-of-dietary-supplements/